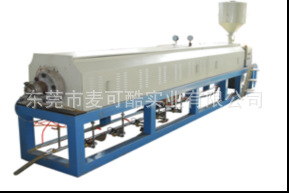

产品型号:ps-800

产品标签:全自动ps泡沫片材机,出厂单价48万

主要技术参数:

Ⅰ主要技术参数 Main parameters 项目 Item | 单位 Unit | 参数 Parameter | 备注 Remark | 型号Model | | FS-FPP70-90 | | 适用材料Applicable materials | | PS | | 成型片材厚度Forming sheet thickness | mm | 1-3 | | 标准片材宽度Standard sheet width | mm | 540-1080 | 更换定型桶宽度可调Replace Shaping barrel adjust width | 发泡倍率Foaming rate | | 12-20 | | 制品容重Bulk weight of product | Kg/m³ | 30-35 | | 制品导热系数Thermal conductivity of product | W/m.k | 0.021-0.038 | | 产量Output | kg/h | 70-100 | | 整机额定功率Rated power | Kw | 120 | | 电源Power supply | | 三相three phase 380v/50Hz | | 外形尺寸External dimension | mm | 22000×7000×3000 | | 整机重量Complete machine weight | Ton | 约10 About 10 | |

Ⅱ生产工艺流程图 Production process chart | | 原料 Raw material | → | 入库 Warehouse entry | ↓ | ↑ | 混合 To mix | 打包贴标 Pack and Label | 发泡剂 Vesicant | ↓ | ↑ | ↓ | 投入料斗 Input hopper | 卷取 Roll on | 发泡剂注入系统 Vesicant injecting system | ↓ | ↑ | ↓ → → | 一级挤出机塑化混合 The first stage extruder, plasticize mix | 静电消除 Electrostatic elimination | | ↓ | ↑ | | 过滤挤出 Filter and Extrude | 牵引展平 pull and flatten | | ↓ | ↑ | | 二级挤出机熔融The second stage extruder, melting mixing | 冷却剖切 Cooling and cutting | | ↓ | ↑ | | 机头模具挤出 Through the extrusion die head | 定型桶定型 Shaping barrel shape |

Ⅲ技术配置 Technical configuration A.自动上料系统 Automatic feeding system 1.上料形式 Feeding style 螺旋上料 Screwed feeding 2.主要参数 Main parameters 上料能力 Feeding capability (kg/h) | 150 |

| 储料箱容积 Storage bin volume (kg) | 300 | 电机功率 Motor power (kw) | 1.5 |

B.一级挤出机 The first stage extruder 螺杆,机筒材质 Screw and barrel material

38CrMoAlA 氮化处理 38CrMoAlA nitriding treatment 2. 主电机形式 Main motor style 交流电机配变频调速 Three-phase asynchronous motors with frequency converters 3. 减速机 Speed reducer 挤出机专用减速机,硬齿面,高扭矩,低噪音 Extruder dedicated reducer,hard tooth surface,high torque,and low noise 4. 加热器 Heater 铸铝加热器,固态继电器无触点输出,智能温控仪控温 Aluminum casted heater, solid-state relay contactless output, intelligent temperature controller control temperature 5. 技术参数 Technical parameters 驱动电机功率 Driving motor power(kw) | 37 |

| 螺杆直径 Diameter of screw bolt (mm) | Φ70 | 螺杆长径比 L/D ratio of screw bolt | 30:1 | 螺杆转速 Max rev of screw (rpm) | 60 | 加热段数 Number of heating zones | 7 | 加热功率 Heating power (kw) | 28 |

C.发泡剂注入系统 Vesicant injecting system 1. 泵种类 Sort of pump 柱塞式高精度高压计量泵,配单向阀控制 注入量由柱塞行程控制 Plunger type high precision and high pressure measuring pump, to match one-way valve to control, the injection volume is controlled by plunger lift 2. 主要技术参数 Main technical parameters 发泡剂种类 Sort of vesicant | F142B或丁烷 Freon or butane |

| 计量泵流量Metering pump flow(L/H) | 40 | 注入压力 Injection pressure(Mpa) | 30 | 压力表 Pressure gauge(Mpa) | 0-60 | 电机功率 Motor power(kw) | 2.2 |

D.液压不停机自动换网系统 Non-stop machine hydraulic automatic replace filter system 1. 形式:液压快速换网器 Form:hydraulic quickly net changing device 2. 主要参数 Main parameters 油泵电机功率 Oil pump motor power (kw) | 4 |

| 油泵压力 Oil pump max pressure (Mpa) | 20 | 网板数量 Filter board quantity | 4个4Piece | 加热功率 Heating power (kw) | 8 |

E.二级挤出机 The second stage extruder 1. 螺杆,机筒材质 Screw and barrel material 38CrMoAlA 氮化处理 38CrMoAlA nitriding treatment 2. 主电机形式 Main motor style 交流电机配变频调速 Three-phase asynchronous motors with frequency converters 3. 减速机 Speed reducer 挤出机专用减速机,硬齿面,高扭矩,低噪音 Extruder dedicated reducer,hard tooth surface,high torque,and low noise 4. 加热器 Heater 铸铝加热器,固态继电器无触点输出,智能温控仪控温Aluminum casted heater, solid-state relay contactless output, intelligent temperature controller control temperature 5. 冷却降温方式 Cooling and temperature-reduction style 水循环冷却,带自动旁路系统 Circulating water cooling ,automatic bypass system. 技术参数 Technical parameters

驱动电机功率 Driving motor power (kw) | 45 |

| 螺杆直径 Diameter of screw bolt (mm) | Φ90 | 螺杆长径比 L/D ratio of screw bolt | 30:1 | 螺杆转速Max rev of screw (rpm) | 30 | 加热段数 Number of heating zones | 8 | 加热功率 Heating power(kw) | 40 |

F.挤出机头和模具 Extruder head and mold 结构 Structure

圆形挤出模头,模口可调, Round of the extruder head,mold mouth can adjust 2. 材质 Material 优质模具钢,经热处理,流道表面粗糙度:Ra0.025μm: High quality tool steel,heat-treated,flow channel surface roughness: Ra0.025μm 主要技术参数 Main technical data

模口直径 Diameter of mold orifice | 依制品宽度确定 Depend on the width of products |

| 温度控制区数 Quantity of temperature control zones | 2 | 温度控制精度 Accuracy of temperature control(℃) | ±1 | 加热功率 Heating power(kw) | 5 |

G.定型、冷却及切割系统 Shaping cooling and cutting system 定型方式 :定型桶定型 Shaping style:shaping barrel 冷却方式:定型桶水冷加外部风环风冷 Cooling style:shaping barrel cools with water and external wind-ring 结构:定型桶,切割刀及机架组成 Structure:shaping barrel, cutting knife and rack components 主要参数 Main technical parameters

定型桶尺寸 Shaping barrel size(mm) | 长720,直径依要求定做length 720 Diameter done as requirement |

| 风机功率 Blower power (kw) | 三相 0.55 Three phrase0.55 |

H.牵引系统 Pulling system 牵引方式:四辊平行牵引,气动压紧。Pulling style:four-roller parallel pull, compress with air drive 驱动电机形式:交流电机,变频调速,减速机变速。Driving motor form:AC-motor, frequency conversion velocity modulation, speed reducer changes speed

3.主要参数 Main parameters 牵引辊数量 Pulling roller quantity | 4个4pieces |

| 牵引辊规格 Pulling roller size (mm) | Φ260×1300 | 电机功率 Motor power (kw) | 1.5 |

I.静电消除系统 Electrostatic elimination system 采用杆式离子棒消静电系统,工作电压7千伏以上,能产生高效、强力的离子风,有效消除静电危险。 J.卷取系统Winding system 形式 Form

双臂气涨轴式 Double-arm air shaft type 主要技术参数 Main technical parameters

卷取重量Coiling weight(kg) | 40 Maximum40 |

| 卷取直径 Coiling diameter (mm) | 1100 Max 1100 | 长度控制 Length control | 计米器控制,长度可调Meter counter control, adjustable length | 传动电机 Driving motor | 力矩电机8n.m×2台 Torque motor 8n.m×2 sets |

M.电气控制系统 Electric control system ps泡沫片材机在线视频

|